Home > Motor Evaluation System > Motor Evaluation System pMOTION-Complete

Motor Evaluation System

- What is motor evaluation system all about?

- Characteristic1

Setting of motor parameters - Characteristic2

Simple operation through menu selection - Characteristic3

Motor loss measurement

Products

- Motor Evaluation System

pMOTION-Complete - Specifications

pMOTION-Complete - Large capacity multi inverter

pMOTION-Driver - Specifications

pMOTION-Driver

Motor Evaluation System

pMOTION® Complete

Fully Automated Measurement of Parameters During a Motor Evaluation!

You can start evaluation immediately because all necessary equipment are available

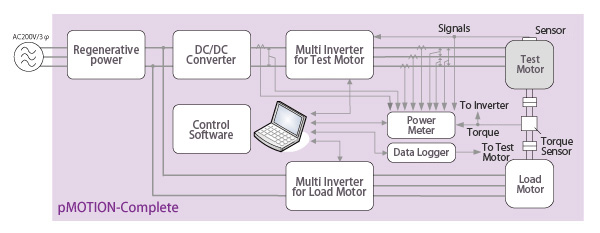

pMotion-Complete evaluation system consists of multi inverter for test motor, load dynamo, highly efficient regenerative power, power meter, data logger, instrumentation software and other components necessary for motor evaluation. You can obtain measurement data conveniently.

Automatic calculation of control gain for driven motor

(Auto tuning)

The control gain of the driven motor (current control gain or speed control gain) will be measured automatically. When the test motor is under drive, the appropriate gain and integration time will be generated from the response of the system (subjected to control) for identification signals. Even without control gain information, you can perform measurement setup shortly.

This system will automatically measure the performance evaluation of the motor

Motor performance is possible with just a preparation of test motor. With multi inverter driving the various motors, besides the advantages of user easy-to-use interface, various measures will be speed up and fully automatic. Upon detecting the characteristics of the motor, product development will be accelerated.

Details is here

Analysis function can be mapped efficiency and displayed form acquired data

By analyzing the measurement file of sweep operation, the map file is output as the minimum current value and the optimum phase angle necessary for outputting a torque with a certain rotational speed, and power factor and efficiency at the time. If the measurement point is insufficient, the map can be created by interpolating between the data.

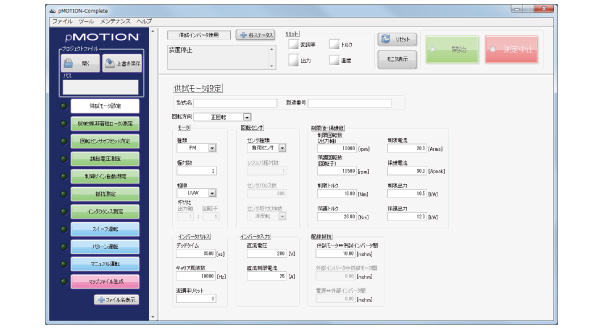

Measurements are clear at a glance with our user friendly software that specialized in motor evaluation

There are a number of measurement patterns available on our system which gives you efficient results from different angles automatically. Upon setting in conditions on the operating PC, where the motor temperature management or various error detection processing are ongoing, characteristic data can be obtained.

Application Examples

●HEV main motor design and evaluation applications

●EV main motor quality assurance applications

●Compressor motor temperature evaluation applications

●Model motor material evaluation applications

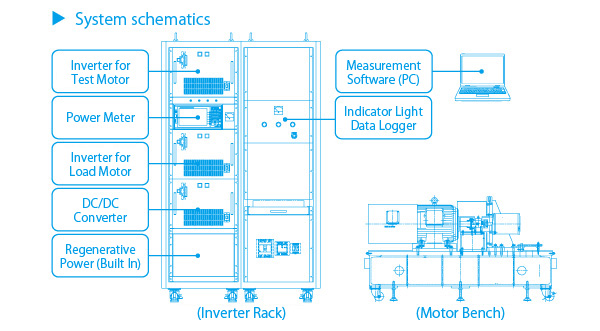

System schematics